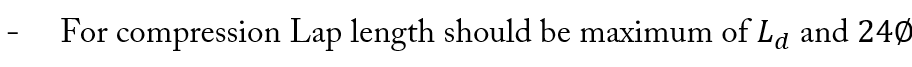

Splicing can be defined as the process of standard length to get bars of desired length is called splicing. It can be achieved by:

For the bars greater than 32 mm (diameter>32mm), lapping is not desirable. In old code of IS it is about 36mm after it amended as 32 mm.

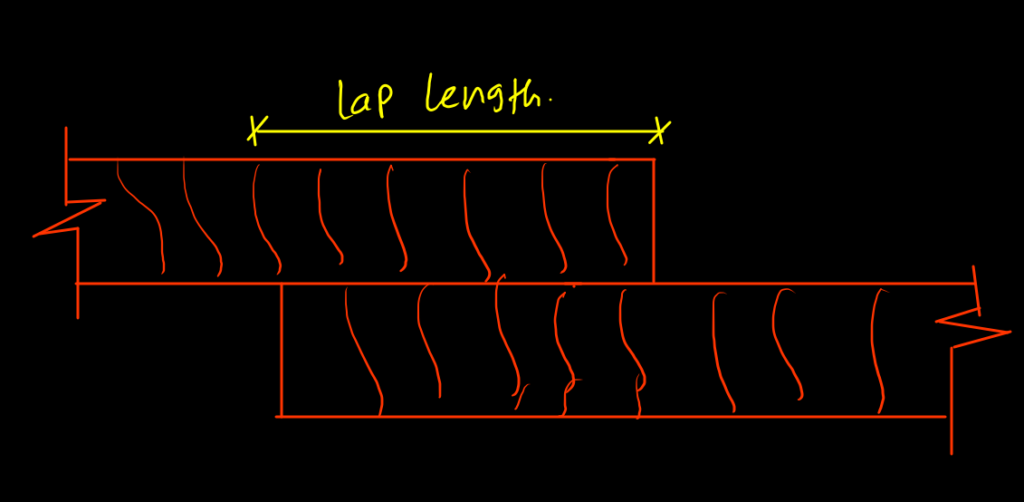

Following lap length must be ensured for splicing

a. For bending Tension

b. For Direct Tension

c. For compression

Note : For bars of different unequal diameter, lap length is calculated corresponding Smaller diameter.

It is not preferable for smaller diameter bar as it effects the strength of steel. It is economical for large diameter bars as lap length is high in case.

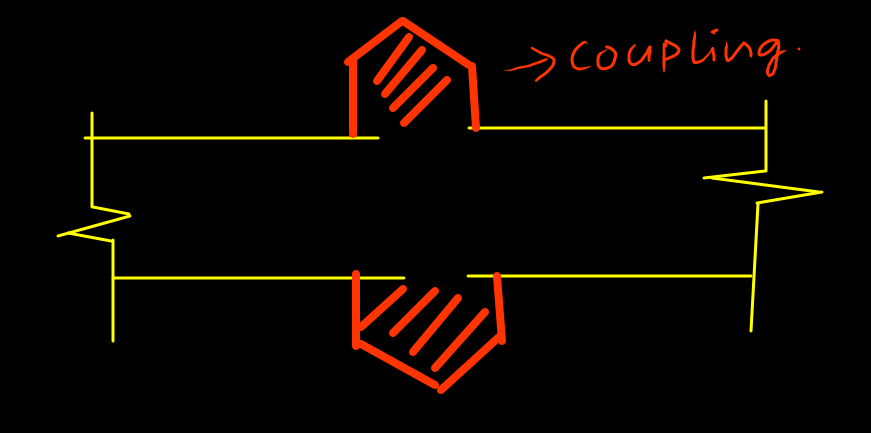

Note : As per Code, Not more than 50 % of reinforcement should be spliced at one location, they must be staggered by distance more than 1.3times the lap length.

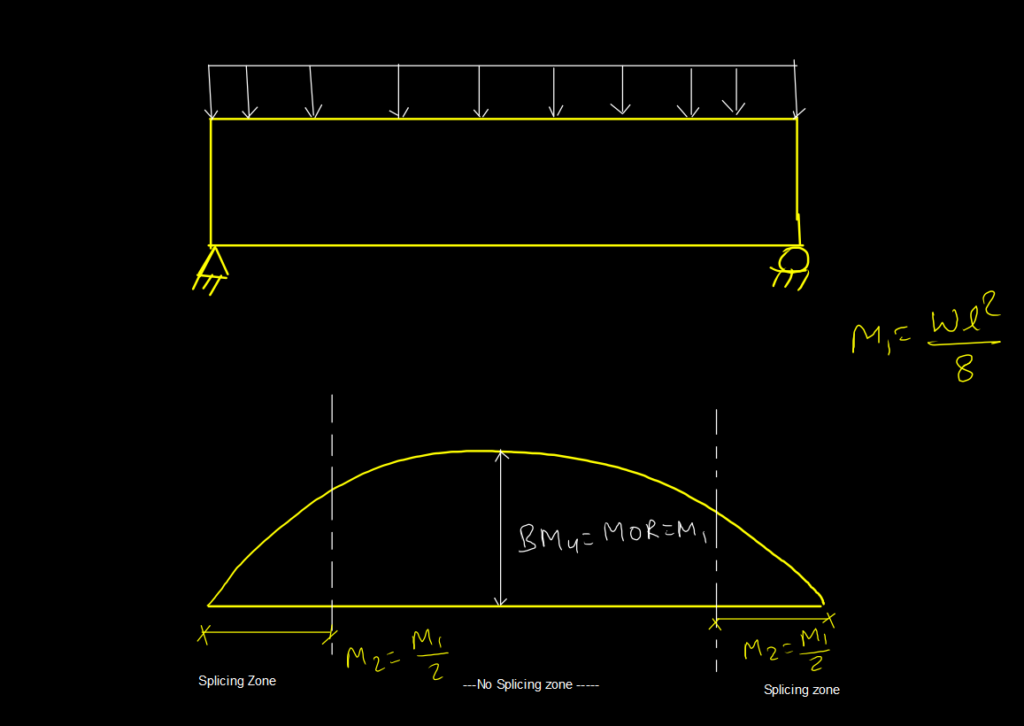

Splicing is not recommended at the location where Bending moment is more than 50% of capacity of the section.