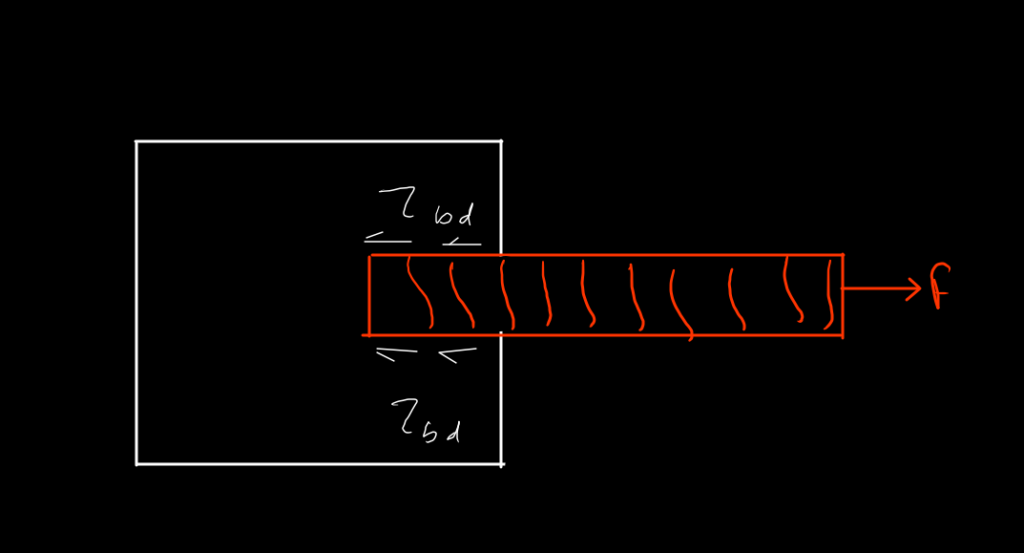

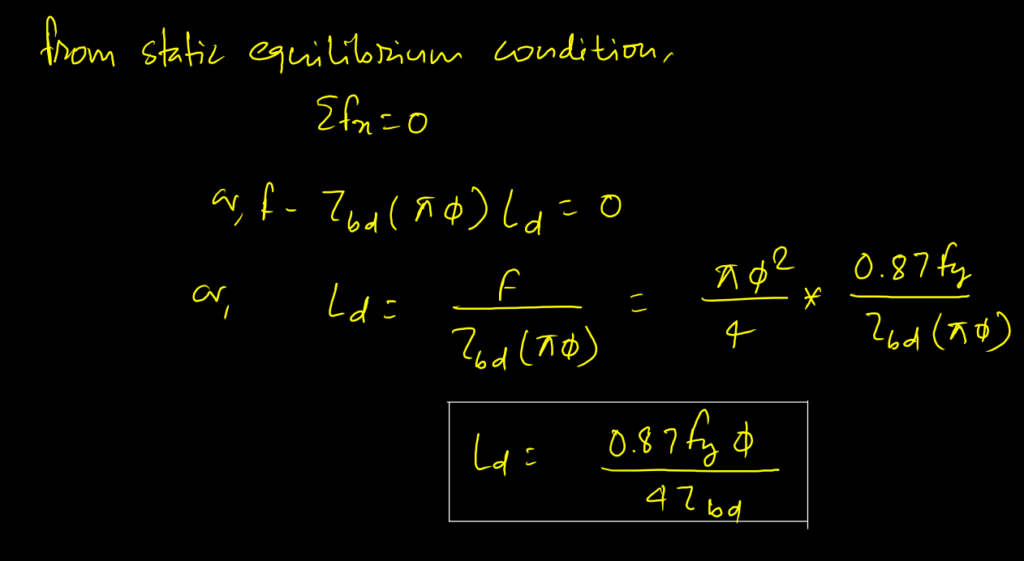

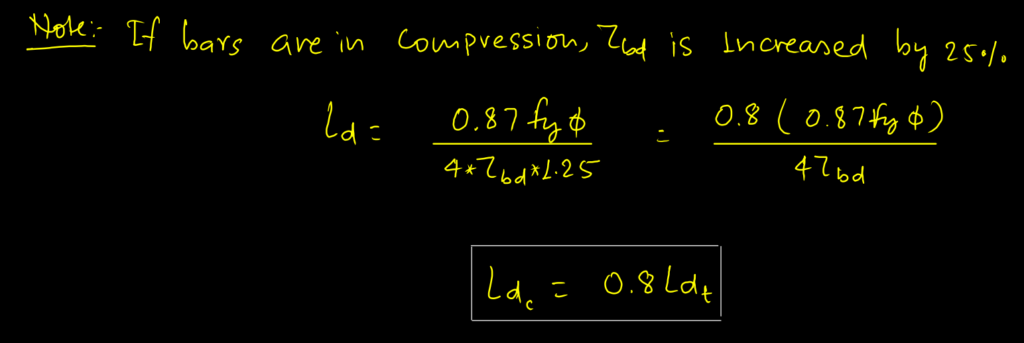

As IS456, the bond stress variation is assumed to be uniform. Minimum length of reinforcement bar required to be embedded in concrete for development of permissible stress in reinforcement i.e. 0.87fy is termed as development length.

Note : Development length of HYSD bars is higher than that of mild steel.

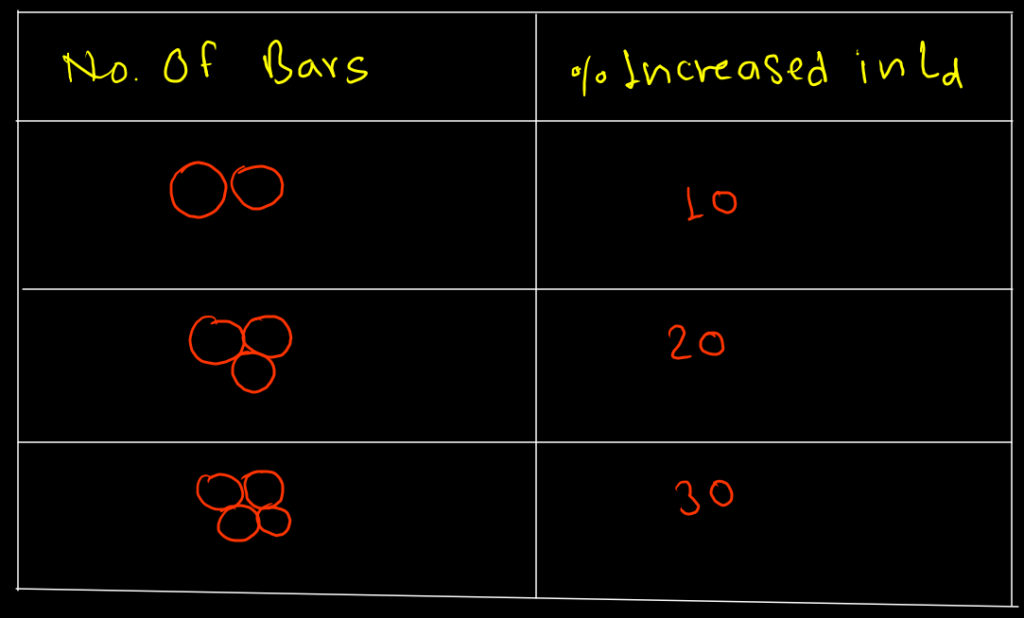

Development length can be increased due to bundling of the bar.

- Pure adhesive Resistance

- Frictional Resistance

- Mechanical Resistance

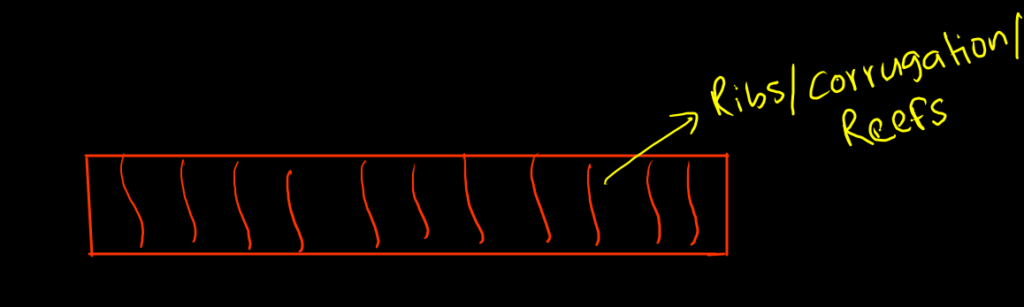

The lining in the bar helps to create the bonds between steel and concrete is known as Ribs also called corrugation, also called as reefs.

- Break up adhesion between concrete and bar.

- Crushing of concrete in front of ribs of bar.

- longitudinal split of concrete along the reinforcement.

- Higher grade of concrete.

- More nominal cover

- Reduce the spacing between stirrups.

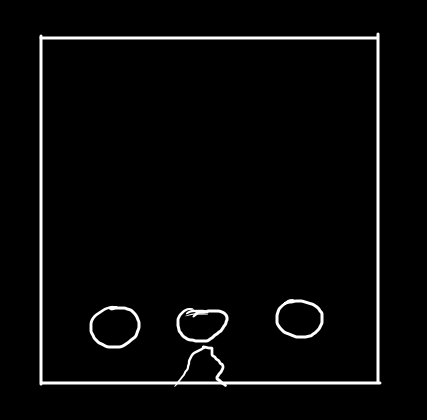

- Use number of small diameter bars

- Use deformed bars

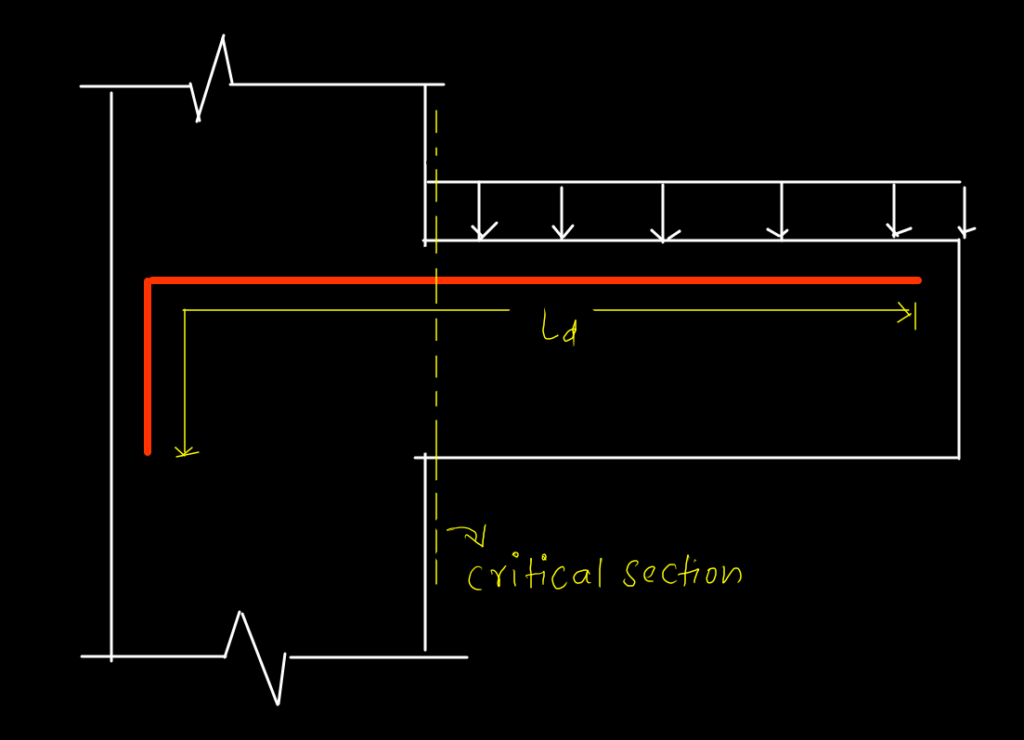

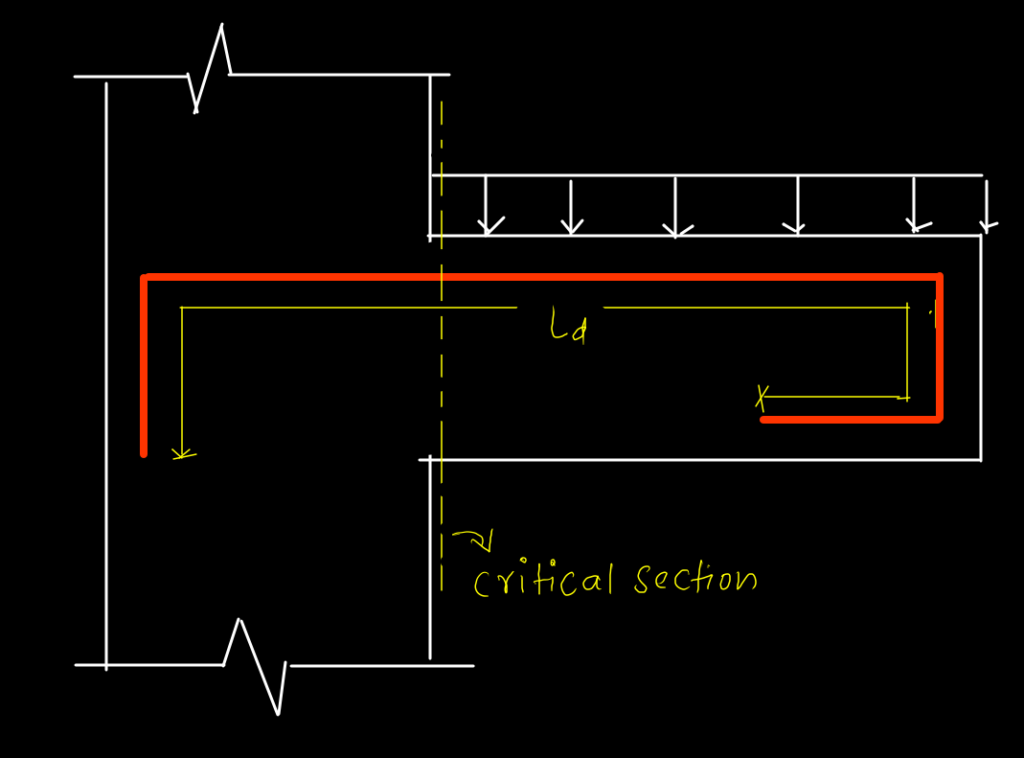

1. By providing Development Length

In no case distance between section of permissible stress of steel and its end should be less than development length (Ld).

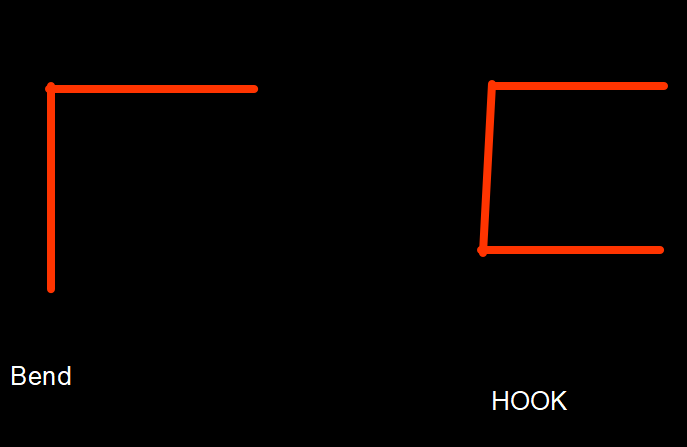

2. By Providing Bend and Hooks

When the required straight development length can not be provided due to limited space in that case Hook or bends are provided.

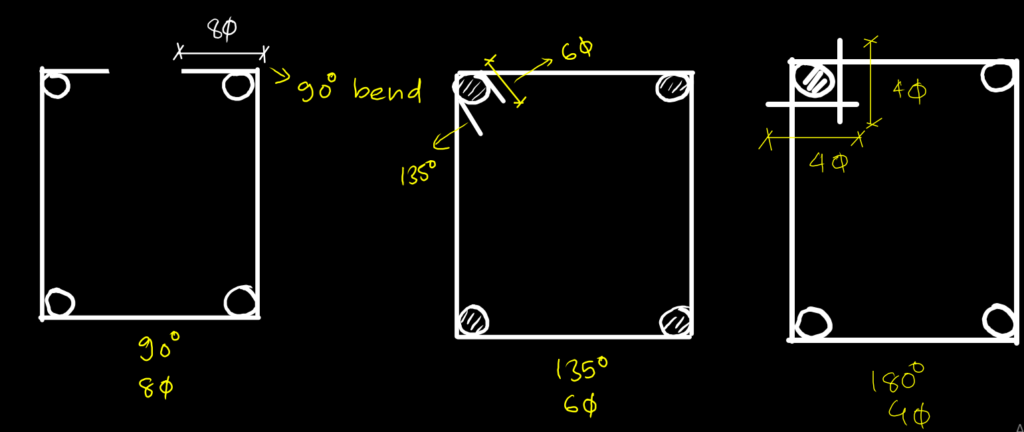

The anchorage value of bend shall be taken as four times the diameter of bar for each 45 degree bend subjected to max of 16 times the diameter of bar.

Note : For L shape bend anchorage = 8 x diameter

For U shape hook anchorage = 16 x diameter

3. Secondary Reinforcement

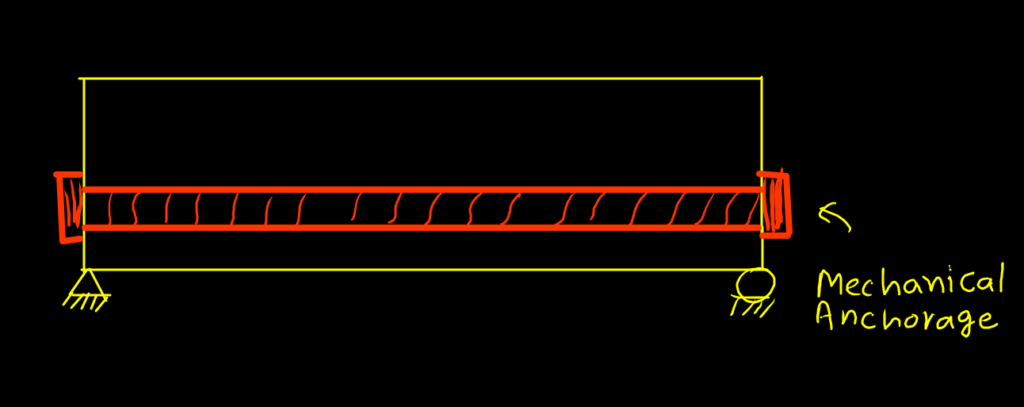

4. By Providing Mechanical Anchorage