Introduction

One of the oldest method of designing is Working Stress Method. If i am not wrong, It is first method of designing of RCC structure. There are many structure, today’s also this method is adopted. There are drawbacks and limitation in the method overcome limit state method came.

Differs from Limit State Method.

- This method is uneconomical than Limit State method.

- Low percentage of steel and high percentage of concrete is used in WSM compared to LSM.

- Due to low stress, Crack width developed.

- Deflection in WSM is observed to be less than LSM due to large section.

Assumption In WSM :

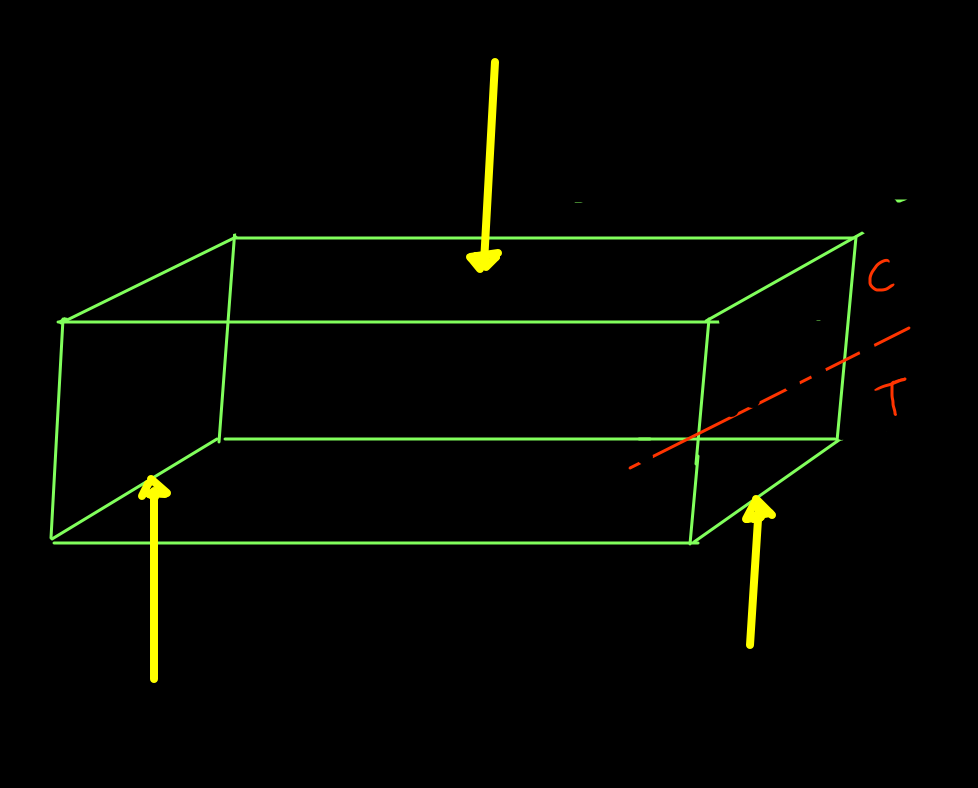

- Plane Section remain plane after bending i.e. variation of strain is linearly.

- Tensile strength of concrete is neglected.

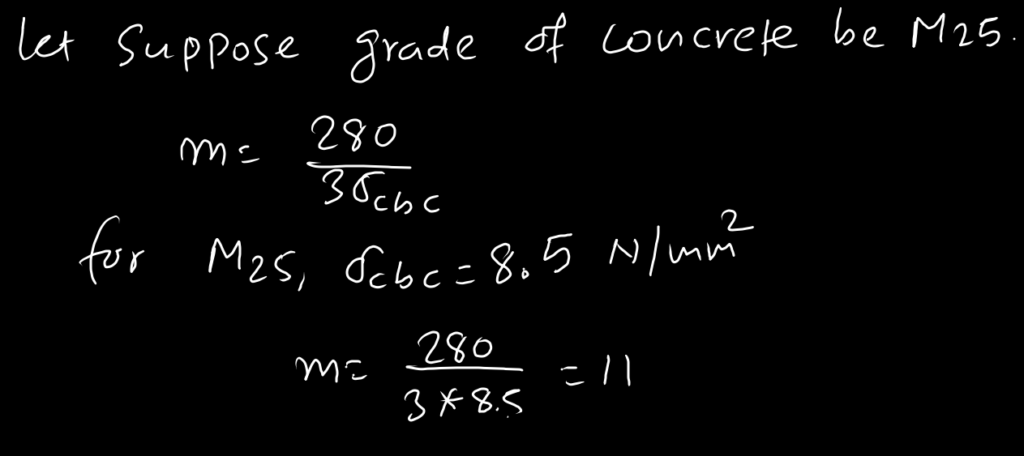

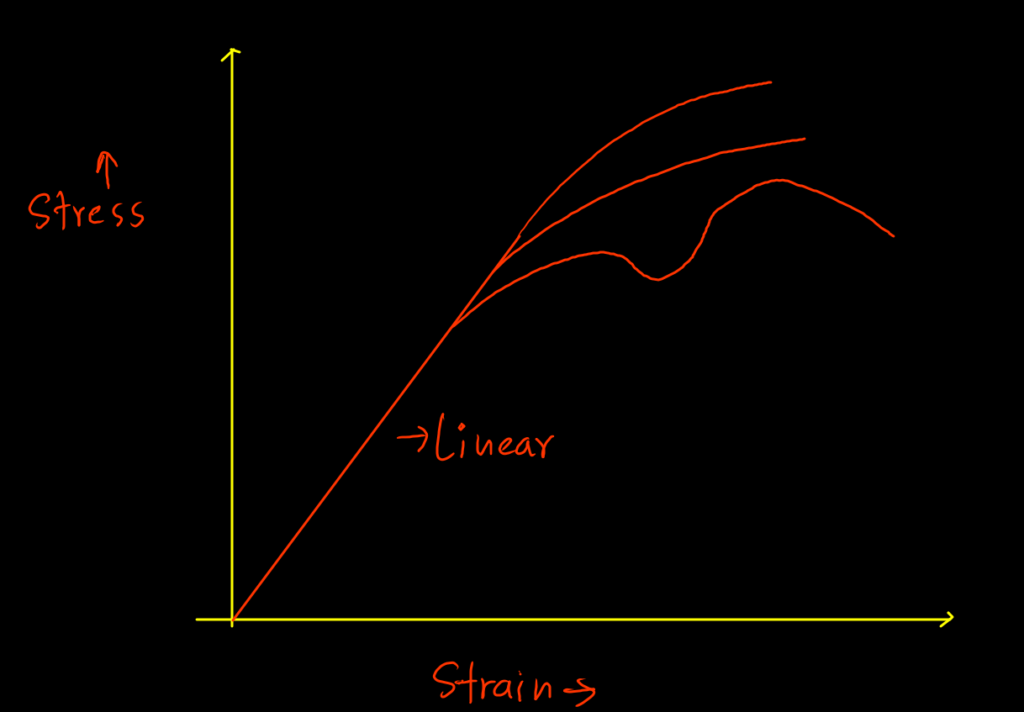

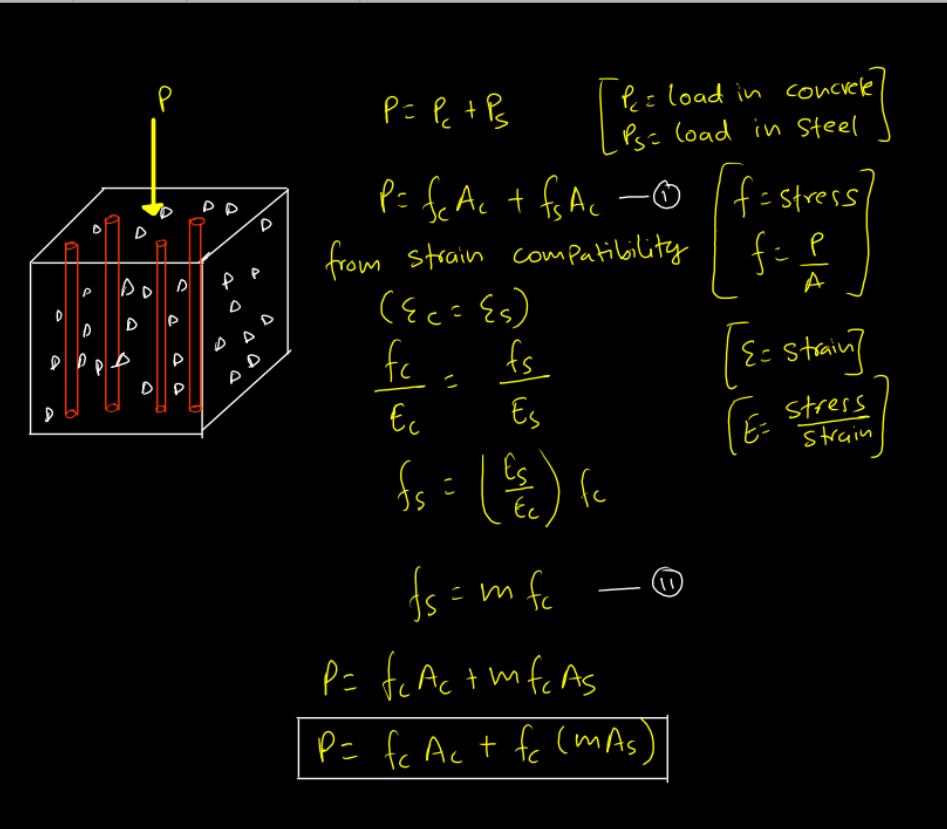

- Modular Ratio, m = Es/Ec

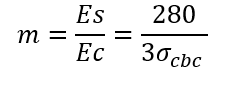

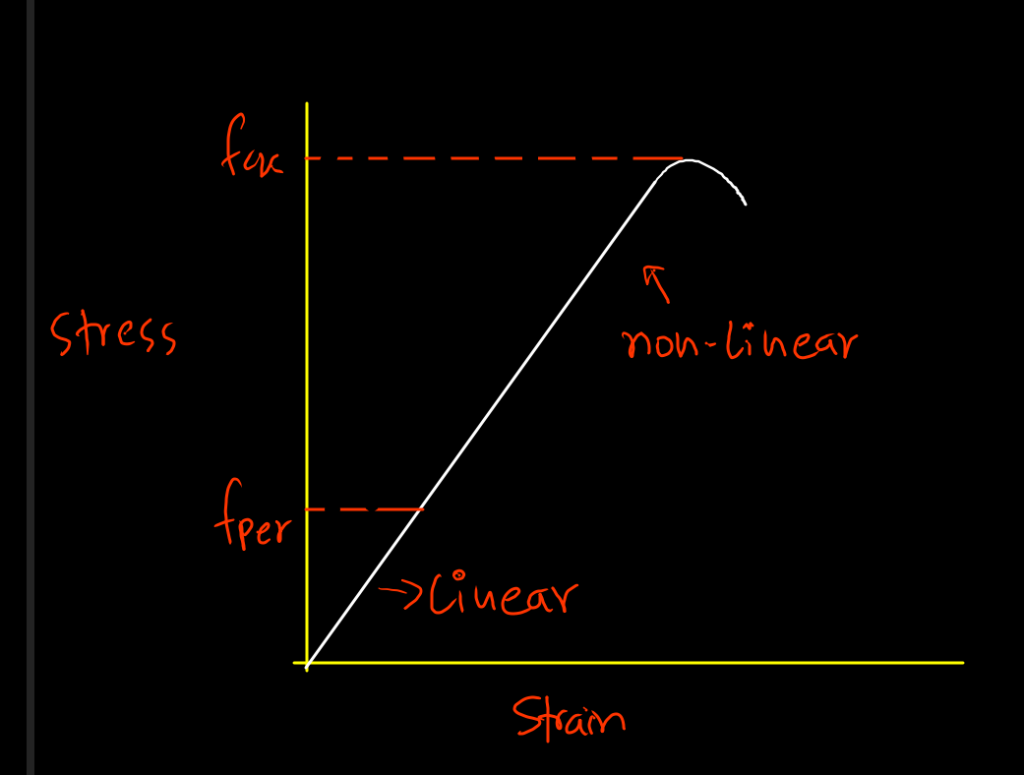

4. Both Concrete and Steel are assumed to be linearly elastic in low stress range.

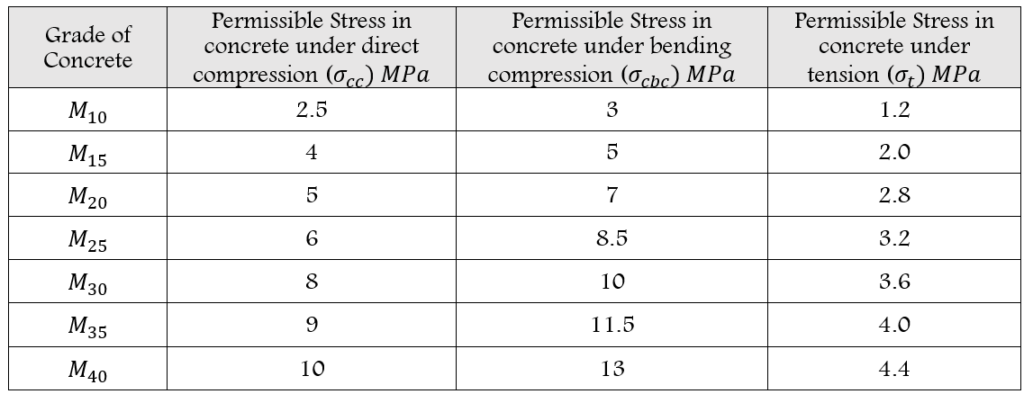

Permissible Stress of concrete

four times permissible stress in concrete under direct compression is equal to characteristics strength, three times permissible stress in concrete under bending is equal to characteristics strength and permissible stress in concrete under tension is 10-12% of fck (approx).

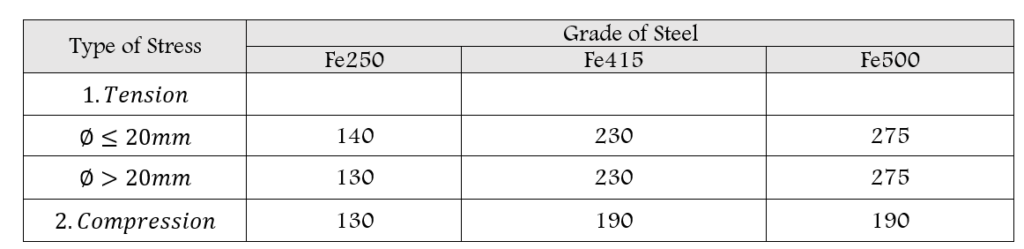

Permissible stress of steel

Significance of Modular Ratio in Design

it is clear that area of steel can be converted into equivalent area of concrete by multiplying modular ratio (m) with area of steel (As).